Hi,

I have built a microvawe transformer spotwelder, I have put a single turn of welder wire for in the secondary and I’m timing it with arduino. Worth mentioning it was/is a 230V transformer. Electrodes are sharpened copper rods. I believe the voltage is still high. The spotwelds it produces are slightly discolored and not as strong as you would expect. Is this design fundamentally borked? Is there anything else I can make to make it better?

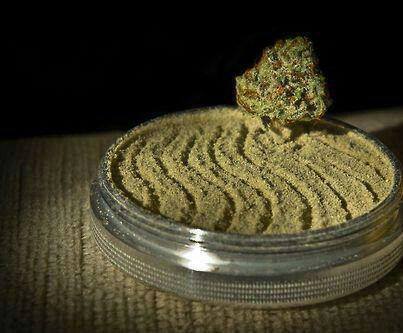

Photo from test stage before it was built into a project box, it is less “shocking” now.

I believe the voltage is still high

I believe there are devices that can measure such things

I did measure, voltage is 3v rms

Microvawe?

What is your question exactly?

Just in case you really didn’t understand: it’s wave, not vawe. It’s a common spelling mistake, especially for people whose native language doesn’t have the w letter.

See radio wave.

Spell check

I don’t have any improvements to offer but I want to mention that I saw a crazy video that used a circuit breaker as a spot welding device. The concept is pretty much right and it is as cheap as it can gets, but it is electroboom kind of crazy and the guy even hurt himself on camera while using it.

If it’s a 240v transformer, the primary will have less turns than a 120v one. You may not have a high enough voltage out of your new secondary because of that.

Would trimming down the voltage on the primary with a triac would help?

You need to go up in voltage, not down.

Try it on 240v. (check your 5v supply can handle that, or power it separately)

I have 230V or 400V three phase. I live in the EU. So this cannot be solved without replacing the winding on the transformer I guess.

If it’s just a matter of getting a larger voltage, then you already got 400V. No need for new windings, unless the insulation on the primary can’t handle 400V.

I need lower voltage. 1-2V on the secondary. I have 3V rms now.