Thanks.

I’ve been working on getting the wheelchair lift working for about three months. It is an older unit, originally solid in 2013, and has passed through two or three owners. It had been “services” by a “certified” technician recommended by the company several months before I bought it. The controller uses five Schneider industrial relays of the type I used for this controller. Four have 24VDC coils and one has a 110VAC coil. The lower half of the relay socket on R2, the Active Security relay, had failed so that circuit was not working. The “certified” technician who worked on the machine removed the fifth relay, the 110VAC dead-man emergency lighting relay and moved the bottom half wiring from R2 to the R110 socket. He tied the coil power from R2 to R110. This left him short a relay. He took the next relay up, the Priority Relay which gave the lift platform priority over all other inputs and put it in the R110 socket then put the 110VAC relay in the Priority socket using the normally closed contacts as a short.

So…I bought a replacement relay socket and relays and put the machine back the way it was supposed to be. Then I started trying to figure out what the inputs and outputs for the controller were supposed to be. I got to the point where I was sure I had everything right and that the controller wasn’t doing anything. I convinced the company to provide some help and they confirmed that the controller was not working properly. They agreed that building my own was going to be more cost effective than buying a new one.

(Interestingly…when I removed the old one and took at look inside it was a voltage divider on the input, relays on the output, and an ATMEGA128 as the controller. Basically exactly the same thing that I built.

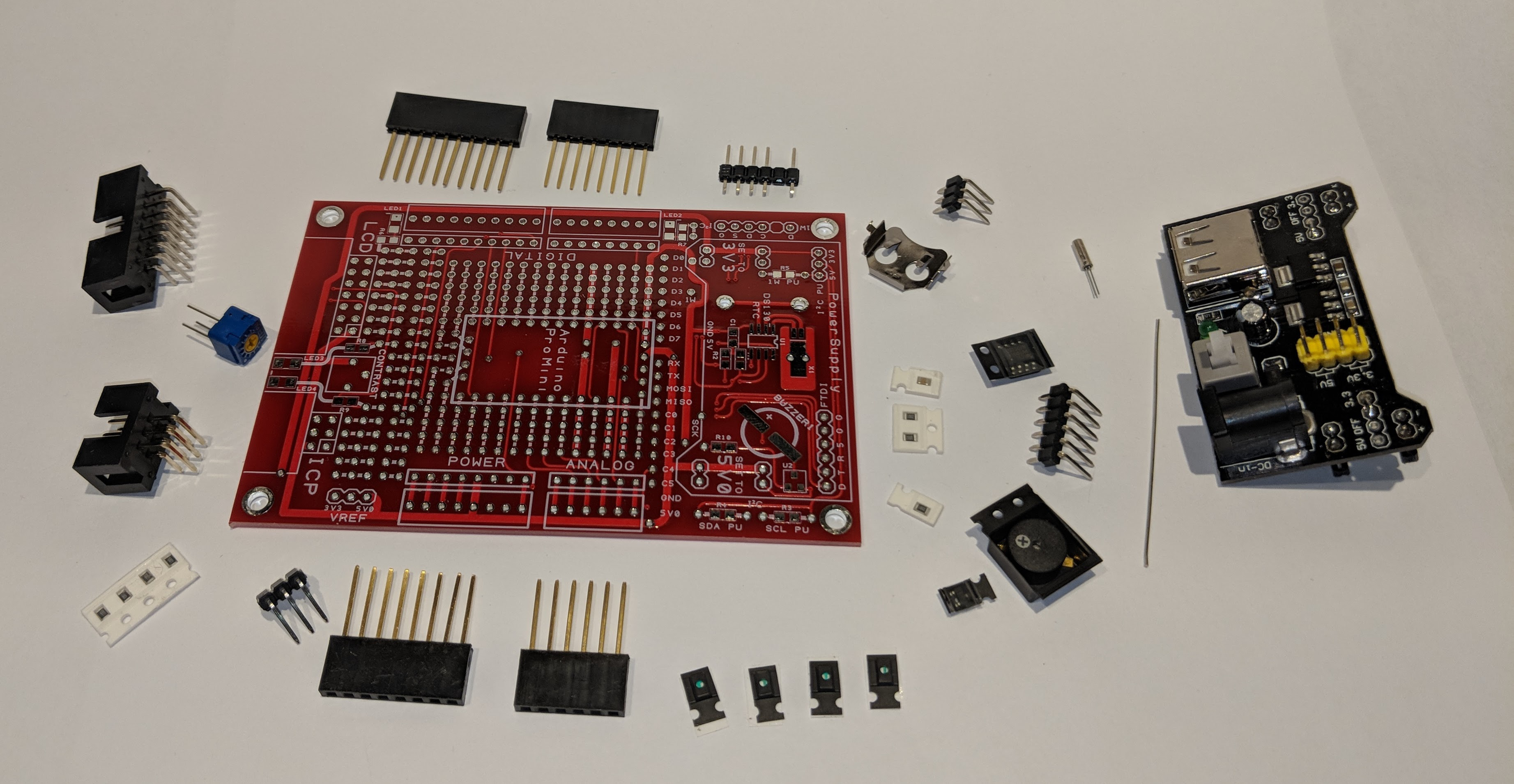

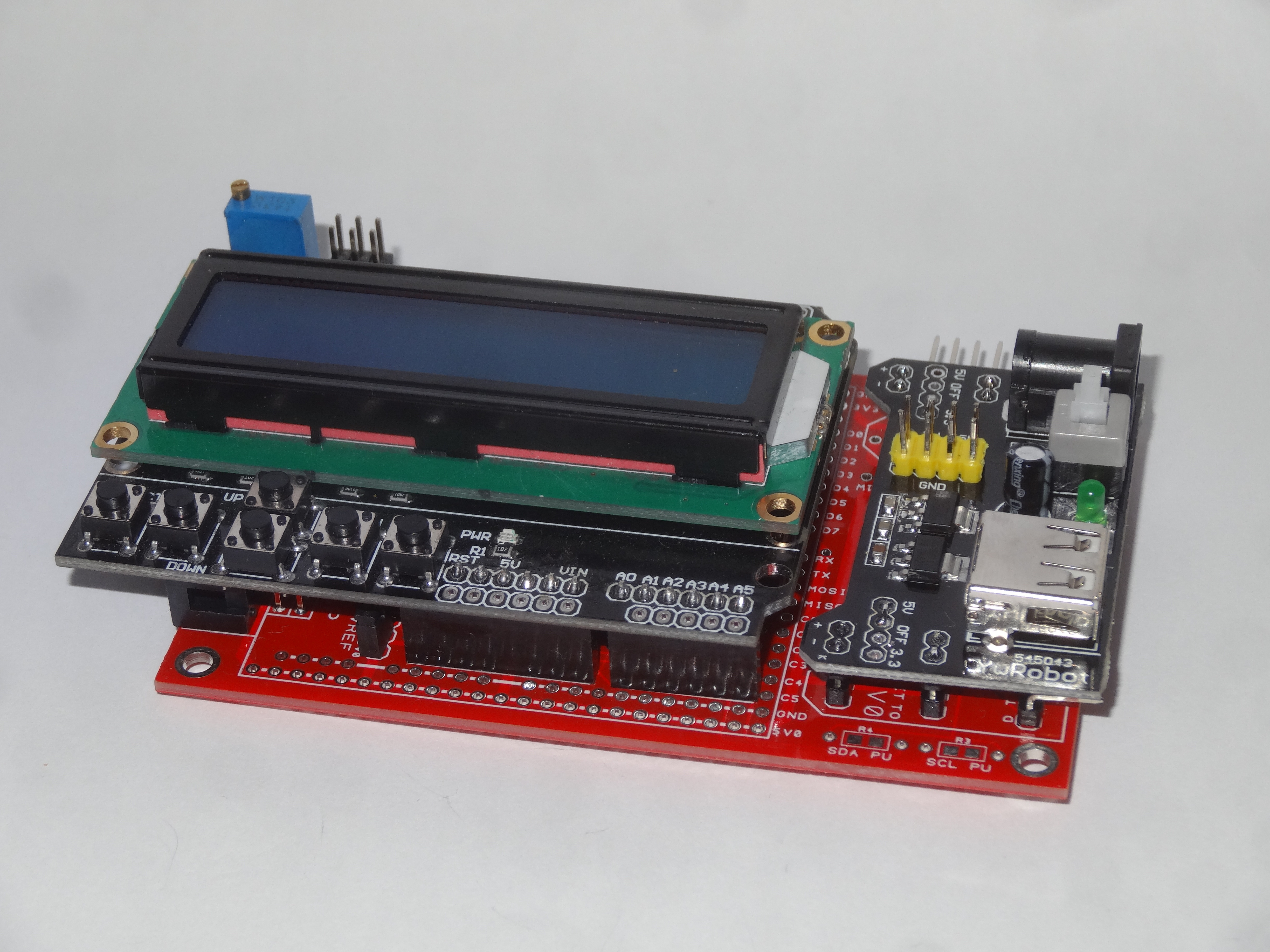

I had the Darlington arrays in my stock. I had to buy the Zener diodes I’m using to reduce the voltage from 24VDC to 3.2VDC.

Building the actual board took about four days. That board had a problem so I built a newer version with some improvements. That took a day.

We own two Epson EcoTank printers and love them.