Good morning friends! I’m still fairly new to 3D printing, although I’m learning a lot more to be dangerous now. I’m printing this part, and I have cleaned and leveled the bed, as I do before every print, and usually have very few issues. This time, my first layer went down almost perfect, with the exception of the bottom right corner being a little bit tight, but as you can see in the picture, every once in a while, I get exactly one line of it not adhering on the first layer. Subsequent layers all seem to lay down perfectly fine, so I’m suspecting bed adhesion, it’s just weird that it’s only in one single line. Anyone ever experienced issues like this, and seen a remedy?

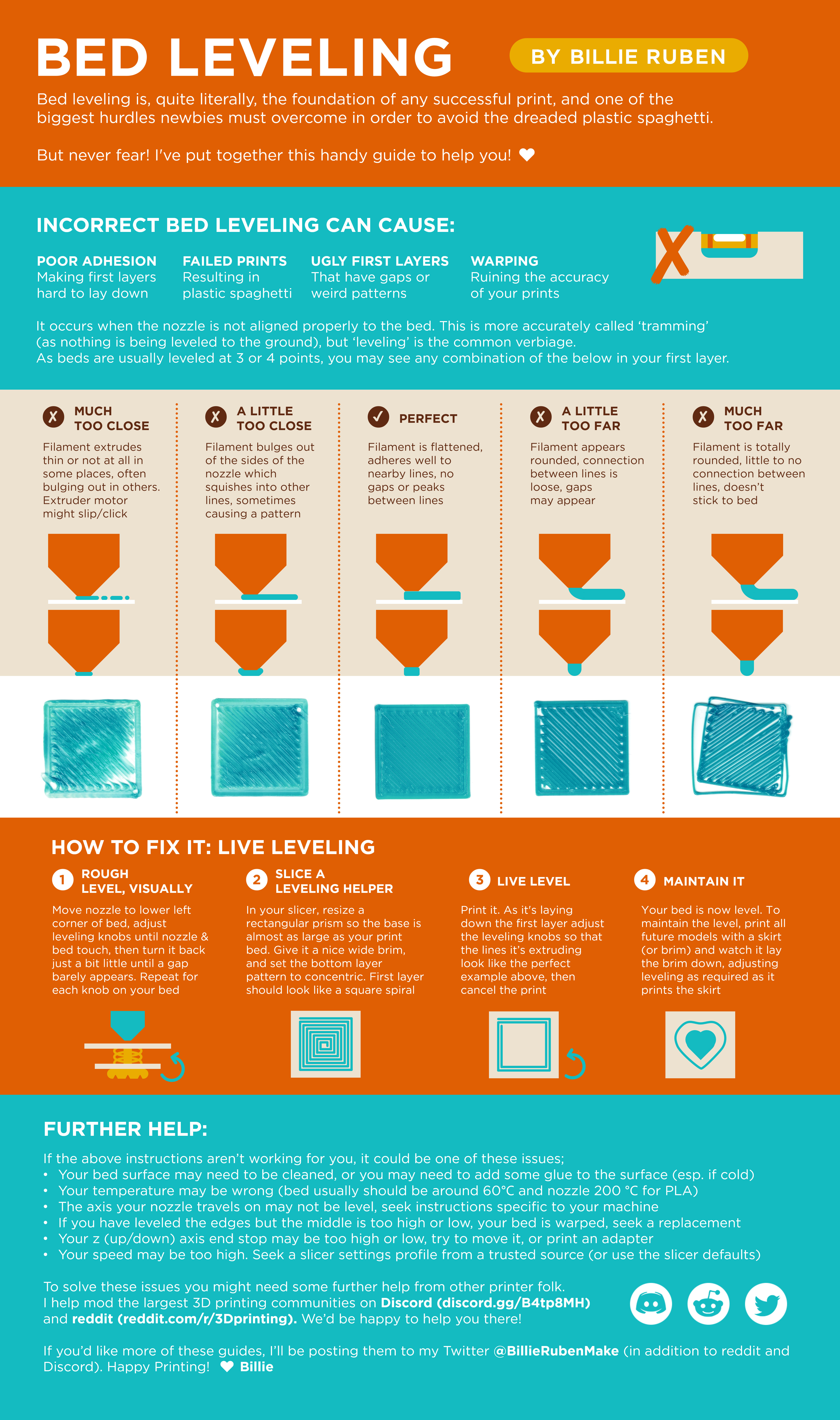

This might help https://imgur.com/a/9faZx36

Waaaay too high

Need more squish. You shouldn’t see gaps between them, they should be smushed together.

I know it’s hard to see in the picture, but this is actually dual color filament and the layers are actually almost perfect. The black you see between the white is actually black filament extruded when the head goes the opposite direction. I hope that makes sense. The only spots it was missing were the random lines in the picture.

Hmm. Even still, it looks way too high. Your outside edges and the brim look like rounded lines. They should be flat.

If you peel up that first layer, can you see between the lines at all? It should be a solid sheet of plastic, even just the first layer.

Still too high I think, even when seeing the two colors now.

Hmm… I would still guess that it’s the height. Try using the auto-home, then go to move > Z axis and lower the Z to zero, then turn off the motor. If you put a sheet of paper between the nozzle and the bed, how much friction do you feel? You should be able to distinctly feel the texture of the paper, but you should still be able to move the paper around with too much force. If that’s not the case, you should try lowering the Z offset and try again until you get the friction just right, consistently, without needing to make adjustments

It’s easy to see. You have three perimeters made with the same colour. And there’s a gap between them.

Nope, look at it blown up Nozzel is way too high You can see the bed through the lines Plus you have a few broken lines, likely lifted as the extrusion is to far from the bed The lines need to be short and wide not tall and thin

Exactly that. The first (and other filled layers) should have no gaps between lines. They only stick well if they are nicely pushed onto the bed.

100%

The good news is that it looks pretty uniform front to back, so the bed is actually probably close to level despite z offset being too high.

I’m actually kind of impressed with how well the lines are sticking despite how little contact area there is!

I’ve had good results using this guide here. It’s primarily for klipper machines but it has marlin equivalents for most entries.

Z-offset is too high Try babystepping it down till those issues go away

New Lemmy Post: An “almost” perfect first layer help (https://lemmy.world/post/10129427)

Tagging: #3dprinting(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md