I want to mount a printed part to a standard 2mm motor axis which doesn’t have any dents or profile. Its just round. If I print at exactly 2mm, it fits for the first few times until it gets too lose and the spinning part sometimes falls off.

2mm is obviously too small for a grub screw. You’re going to need a brass adapter or glue. Either way, it’s probably not coming off (easily) when it’s on there.

Sand a flat to create a D profile and then use a shaft collar and set screw

deleted by creator

That you’re looking for is called a flange mount. If you search your favorite search engine with “2mm flange mount” you’ll find some results. I do wonder how much torque you’ll be able to transfer, but given the shaft size I suspect you’re not looking at big loads.

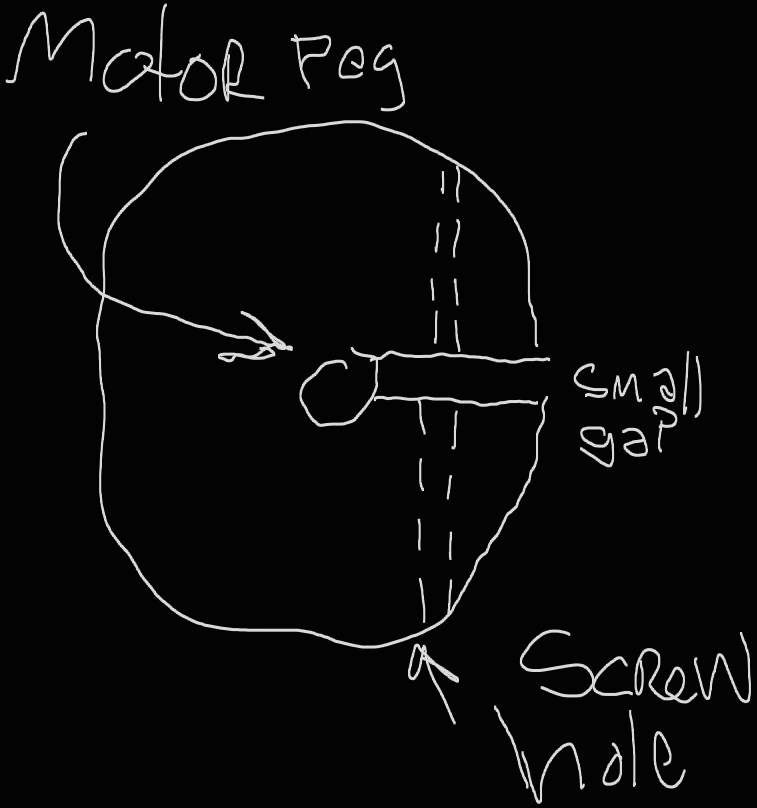

Instead of making the hole the exact size, make a small gap so you can use a screw and nut to clamp it down on the peg

But doesn’t that create an offset weight? My part will probably spin at several thousand RPM.

deleted by creator

I will be using PLA

deleted by creator

Rough sand the axis and add glue