Thanks again!

Does this look OK, to your trained eye then?

Thanks again!

Does this look OK, to your trained eye then?

Thanks. It has been fun, both doing the software, where I feel at home, but also the challenge of trying to do electronics, where I am completely lost :D You can’t imagine the amount of DC converters I have burnt out, or my absolute confusion why I couldn’t turn a motor on and off using a couple of relays! I must confess I still don’t understand, but at least now I know.

Sorry I forgot to ask: I should cut the SENSE-A connection to ground right?

Oh, wow!

Very nice! Thank you so much for doing this!

Is it correctly understood that the “Sense” line can be hooked up directly to the ADC input on the Pico?

Now, just because I am quite ignorant when it comes to all this, I will venture to ask: This is better because it is closer/faster/more exact than using the Hall current sensor, or? With my complete lack of understanding, I had the impression, that I could more or less “just” connect the sensor to the “right spots” and directly to the ADC input on the Pico, and my work in the Pico would be similar to this setup?

Don’t get me wrong - I can see this is much more elegant - and won’t be bothered by whatever else might use power on the same rail. But since it might be simpler for me to use a more “out of the box” component like the sensor, instead of my bad soldering of several discrete components… Also however ridiculous it might seem it is much easier for me to source 5 modules - than 5 of each of these components (I would have to buy many of each, and waste most).

So I have to ask. :-)

OK… I understand very little of this :( I am a software person. But could this comparison not be done with some hysteresis? The part count is not important as long as the parts aren’t terribly expensive, since this is exclusively for my personal use.

It is a networked window opener/closer for my house, all with parts sourced from China, since the commercially available openers are very overpriced IMHO. Which I guess also speaks a lot to the fact that I am a man with more time than money…

That sounds very cool - and way beyond my own understanding :-)

Is this something you could actually help with sketching out for me?

I found the datasheet for the L298 and I can see that for my use (I am using just out 1 and out 2) it should be pin 1 (Sense A) that should be relevant, right?

This looks like it is connected to gnd on the driver board (I can easily cut this connection).

Unfortunately I don’t understand what a current shunt is? :-)

It has me slightly worried that it says that pin 1 can go to -1v which I think would break the ADC input?

As far as I can tell the ADC input on the PICO accepts from 0 - 3.3v right?

Thanks a bunch for looking at this!

Ah… Since I am not a smart man, I have already invested too much (for the project) in several of these motor drivers. :-(

Thanks for taking time to look at this! :)

The issue is that if something is blocking the motor, or the limit sensor is not working, the motor should stop before burning itself out or breaking stuff.

I did buy a hall effect current sensor (https://www.aliexpress.com/item/1005006222090940.html) that I was thinking of connecting to the pi pico on an interrupt enabled pin, so I could cut off the engine output at the source, and alert my upstream controller. But I just couldn’t wrap my head around how to implement it.

Another option that I considered was putting some kind of fuse on the 18v rail and try to figure out how to detect if the 18v rail was dead and feed that to the pico - but then I’m not really sure how much simpler (if at all) that would be.

The picos inputs are 3.3v btw.

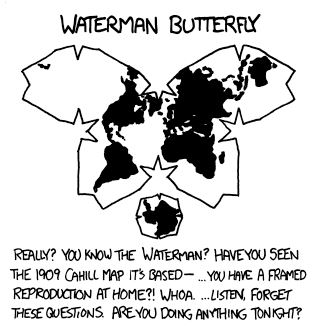

I don’t quite get this. The human head, like the globe, is not flat. Shouldn’t that be reflected in the projections? When projecting the earth in Mercator, we see the whole earth, not simply a “profile” of earth. I would expect a projection of a head to include the whole surface of the head, not a simple profile. How is this actually factual?

Even if we were to accept that at face value, it does not change the fact that libraries are paid for by taxes, which was my exact statement. My point was not what you seem to interpret in any case. My point, if any, was that we get a lot of really cool stuff for taxes… And also that, as most other things, they are not actually free.

Thanks again for looking at this!

The NTC meassures very low ohm, in circuit it’s around 14 ohm.

The markings on the “receiver” board are: +27v, gnd, -27v and “mute”.

I would like to try to do some “divide and conquer” debugging, as the total number of components is rather low. I would like to try to eliminate the different “blocks”. Like I can connect it up, and measure the voltage after certain “stages”. Maybe after the inrush current limiter? To my very limited understanding that should be right at the end of the AC block/stage? Maybe dividing the board into 3 or 4 stages like this I could start to narrow down the issue?

I am guessing the MOV is the component marked MOV on the board, its markings are: TVR 07471. Can I test this "in-circuit, or must I de-solder it to test it?

In-Circuit I measure around 470kohm

Thank you for taking the time to help out :-)

I have attached a couple of images. I figured the PSU is the issue, since there is 0v between the black lead and the other leads on the connector to the other parts - the one in the bottom right corner on the attached overhead.

I measured the “MF 72 10D13” for connection, and it is OK. I then measured the two large capacitors (in-circuit) and they both come out fairly close to the 390uF they are rated as. I also tried to measure what I think are 4 transistors attached to the heatsinks. But am uncertain of the results there, as I can’t follow enough of the circuit to understand the results - and I am not even sure they are transistors - much less if they are npn or pnp :-) They are marked as Q1, Q2, D6 and D7 on the board.

When visually inspecting the board and components, the only thing I thought, might be “odd” was the “browning/darkening” around the circuitry near where “R1” is located.

I got the 30 amp. My thought was that the motor uses up to around 20 watts when running so a little more than 1 amp, and as far as I can tell, it tries to pull around 6-10 amps(!) when stalled/almost stalled. I think this should mean a fairly large spike, that I should be able to detect even with the 30A device.

But of course it is probably just absurd overkill, and will make my life more complicated. Fortunately they are absurdly cheap and easy to buy, so if the resolution turns out to be a problem, I can get another range, when I have some empirical data. The other ranges should plug in, in the same place right?